Services That Support Every Stage of Tablet Coating

Empowering the pharmaceutical industry to solve film-coating challenges with smart, science-driven solutions that deliver better, faster, and more affordable results.

Diagnostics Service

What You Get

A diagnostics report

What’s Included

Capacity and cost optimization potential

Based on batch size variation

Based on coating weight gain variation

Film thickness distribution

Film thickness density

Sensitivity analysis of coating environment

3-D plots of temperatures, flow rates, and humidities

Impact of inlet air dew point on coating humidity

Characterization of process efficiencies

Coating deposition efficiency based on material balance

Thermal efficiency (heat loss) based on energy balance

Spray distribution efficiency based on coating uniformity

Physical properties of

Tablet shape, volume, and densities

Heat capacities and latent heat of vaporization

Lower explosion limit for solvents

What You Need

Formulation properties

Tablet weight gain

Tablet dimensions and properties

Coating solution solids content

Equipment dimensions

Processing conditions

Timing

15-30 minutes

Contact us for input template and sample report. Assistance will be provided to help setup the input file.

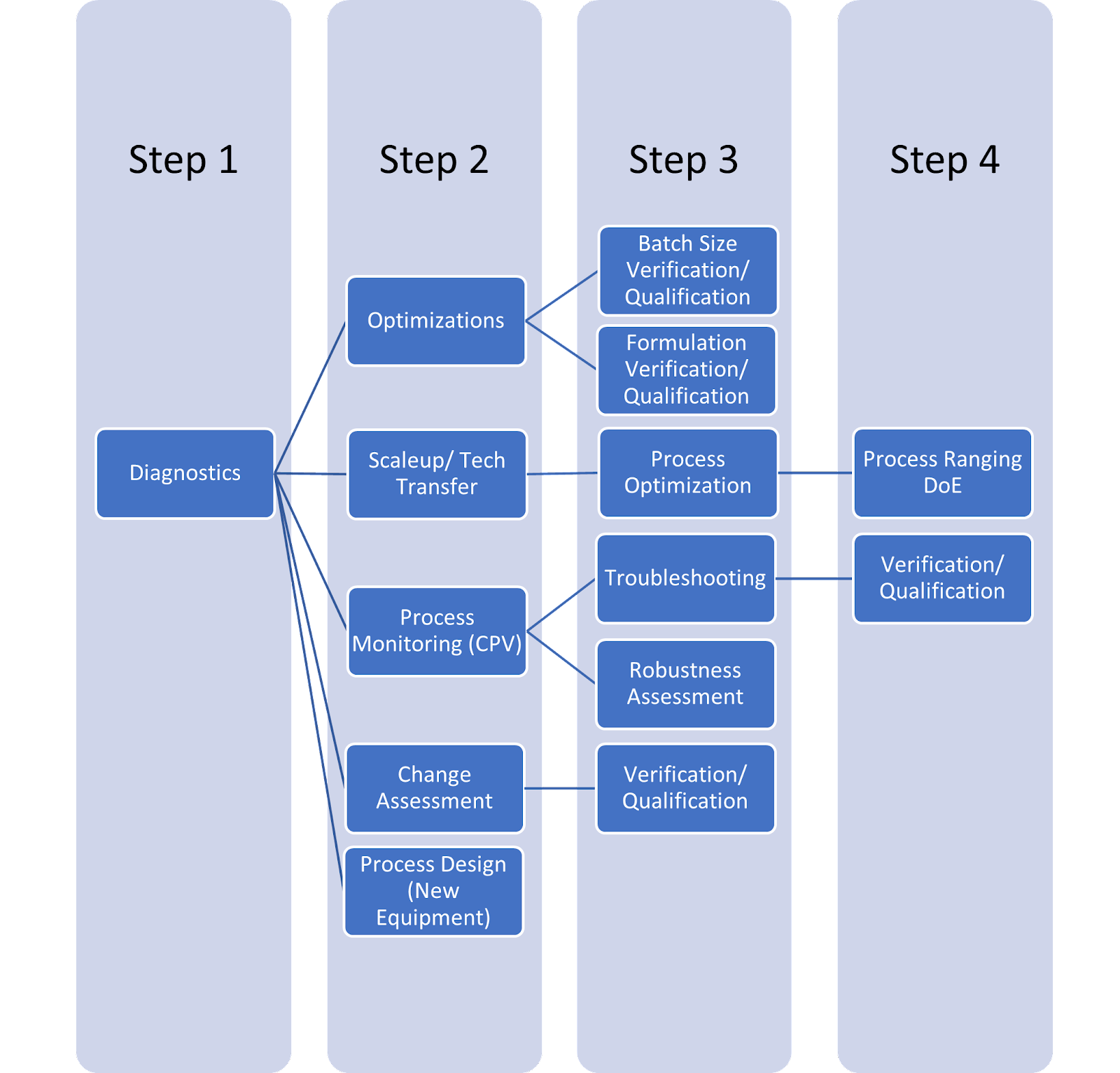

Step Process

Other Services

We guarantee better, faster, cost-effective solutions.

Contact us for details on digital twin support for product lifestyle activities.